Motor Specialty Inc. (MSI)

At Motor Specialty we have been manufacturing high-power motors to satisfy our client needs for over 70 years. We take pride in maintaining long-term relationships with our clients. Our team of trained professionals design and build parts and motors that you deserve.

What We Make

ALL PRODUCTS

Motor Specialty Inc. has Been Building Custom Motors Since 1947.

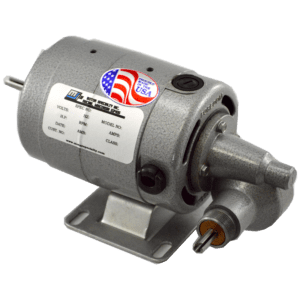

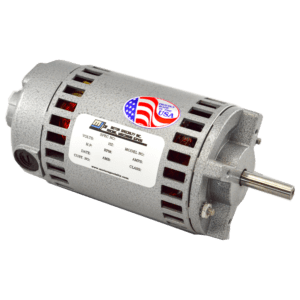

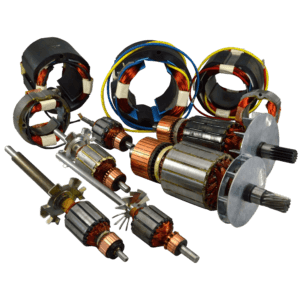

At Motor Specialty Inc. we design and manufacture custom universal, shunt wound, permanent magnet fractional & integral horsepower electric motors, gearmotors and armatures & fields up to 2 HP, 12 volts to 240 volts.

We can design or modify existing models to your specifications with various mounting options available to meet your needs. Motor Specialty Inc. has been serving OEMs with quality motors for over 70 years.

Why MSI?

Our CapabilitiesMotor Specialty has supplied us for over 20 years and we have experienced nothing less than exceptional customer service and unmatched quality. Their employees are truly proud of what they do, and it will show through the products they build for you.